Greg Mackie Sheet Metal

Large-volume production support (500+ units), hands-on fabrication experience, and CAD optimization for punching, folding, and laser cutting operations.

Project Overview

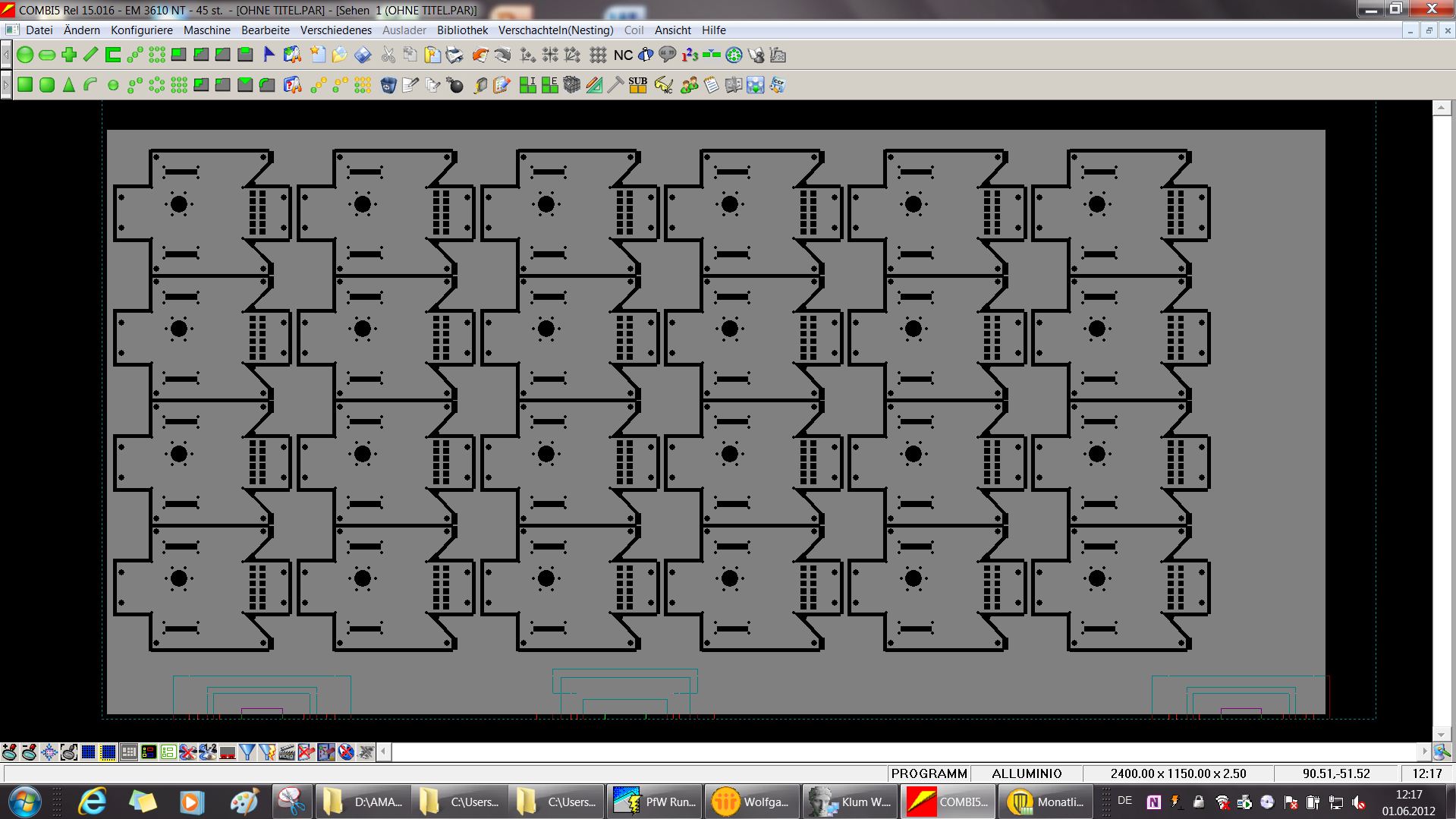

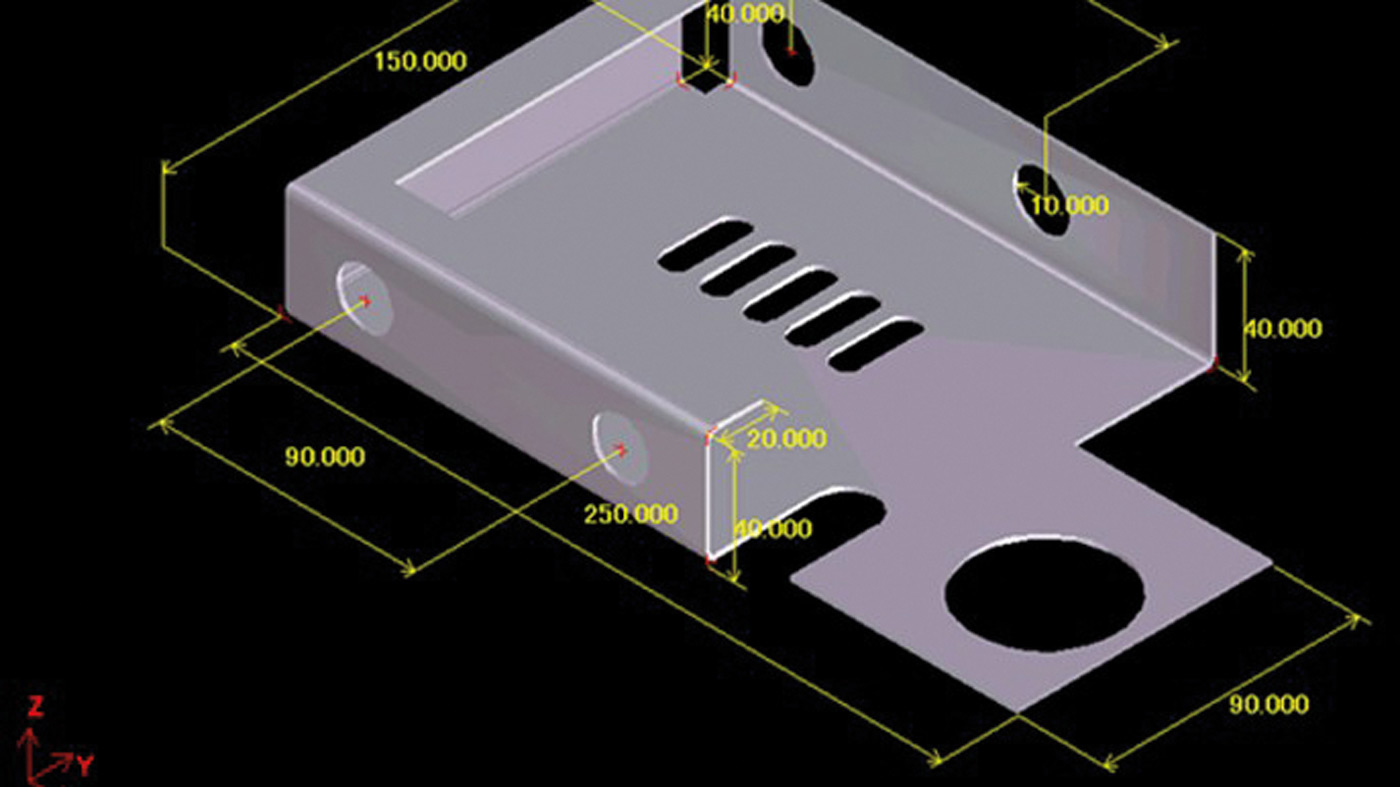

At Greg Mackie Sheet Metal, I supported large-volume production runs, often exceeding 500 units. My role extended beyond CAD: I translated models into drawings optimised for punching, folding, and laser operations, then stepped out onto the floor to run the machines myself. This hands-on exposure gave me direct feedback on cycle time, bend sequencing, corner relief behaviour, and the subtle differences between "fits in CAD" and "flows in production." I worked closely with technicians to resolve ambiguities in drawings, improve consistency, and reduce friction in turnarounds.

Services Provided

- CAD model translation into production-optimized drawings

- Drawings optimized for punching, folding, and laser cutting operations

- Hands-on machine operation (punch, fold, laser equipment)

- Bend sequencing and corner relief optimization

- Direct collaboration with technicians for drawing clarity

- Production consistency improvement and turnaround time reduction

- Cycle time analysis and process flow optimization

Key Deliverables

- Production-ready fabrication drawings for 500+ unit runs

- Optimized flat patterns for punching, folding, and laser operations

- Process documentation improving manufacturing repeatability

- Drawing packages with reduced ambiguity and improved consistency

- Manufacturing feedback integration improving quality at scale

Growth Takeaway

Running fabrication equipment myself strengthened my understanding of manufacturability. It taught me to design for the process, with the process, and sometimes around the process, improving quality and repeatability at scale.

Get in Touch

Ready to start your project? Contact us today for a consultation

Phone

(+61) 0451 905 568